Counter Flow Heat Exchanger

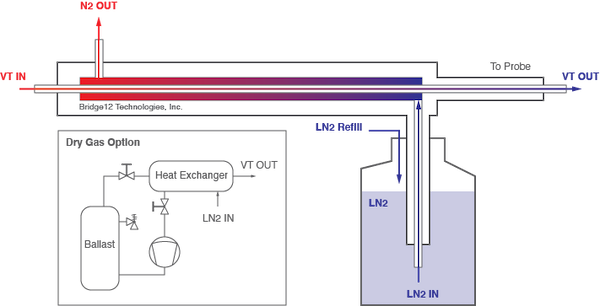

Unlike using immersion coils to cool the VT gas, the Bridge12 heat exchanger uses two gas streams that flow in opposite directions. This avoids condensation inside the heat exchanger. In one direction, a vacuum pump pulls liquid nitrogen through a capillary from a storage dewar into the heat exchanger. The LN2 evaporates and the cold nitrogen gas is cooling the VT gas, which is travelling in the opposite direction. Depending on the vacuum and therefore the amount of LN2 that is pulled through the capillary the temperature of the VT gas can be controlled from room temperature (RT) down to < 90 K. The storage dewar is not pressurized and refilling the dewar can be done at any time. The entire heat exchanger assembly is thermally insulated to guarantee efficient operation and minimal cryogen consumption.

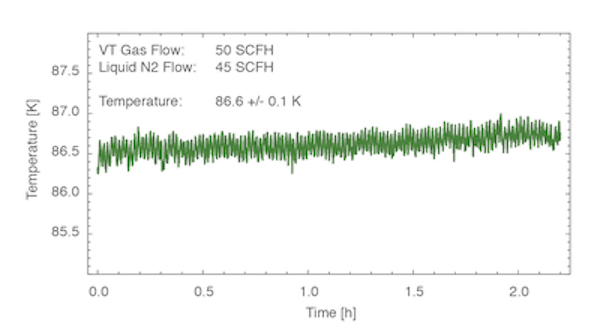

1.8 l/hr LN2 to Maintain a VT Temperature of 86 K

The heat exchanger is designed to operate very efficiently. At the lowest temperature of 86 K, and a VT gas flow rate of 50 scfh (23.6 l/min) only 1.8 l/hr of LN2 is consumed, corresponding to about 45 scfh (21.2 l/min) of nitrogen gas. When using a 50 l storage dewar low-temperature operation for 24+ hrs is guaranteed.

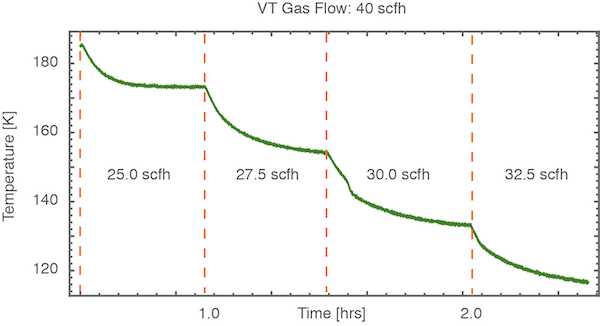

Variable Temperature Control Over a Wide Range

The output temperature of the VT gas can be regulated by adjusting the VT gas flow rate and the amount of liquid nitrogen that is pulled by the vacuum (see back page). Once a stable flow rate is established the temperature fluctuations are very small. To accurately set and stabilize the VT gas temperature, the built-in heater element of the NMR probe is used.

Flexible Design

The Bridge12 counterflow heat exchanger has a very flexible design to accommodate the individual researcher’s requirements. It can be equipped with a cryogenic bayonet fitting (as shown in the photograph) to connect individual transfer lines. Alternatively, the heat exchanger can be equipped with a transfer line that is directly connecting to the NMR probe. Optionally, an LN2 level sensor is available to monitor the cryogen level inside the storage dewar and to aide automatic refills for long-term operation.

Technical Specifications

- Temperature Range: < 90 K - RT

- Typical cryogen consumption: 1.8 l/hr of LN2 (45 scfh, 21.2 l/min nitrogen gas) to cool VT gas to a temperature of 86 K at a flow rate of 50 scfh (23.6 l/min)

- All gas connections are suitable for 1/4 in. push-to-connection fittings. Adapters for metric hardware are available.

- A LN2 level monitor for automatic refills is available as an add-on.

- The system includes:

- The counter-flow heat exchanger

- Two flow regulators to regulate the LN2 and VT flow

- Diaphragm pump

- 50 l LN2 storage dewar

- All required hoses and connectors and valves